TSC is committed to improving energy efficiency and ensuring that electricity consumption and other energy consumption are reduced by at least 1% annually. Currently, both the Li-Je and I-lan Sites have implemented environmental protection plans that are based on their energy consumption. They conduct inspections on equipment that consumes a significant amount of energy and continuously upgrade to new energy-saving equipment as replacements.

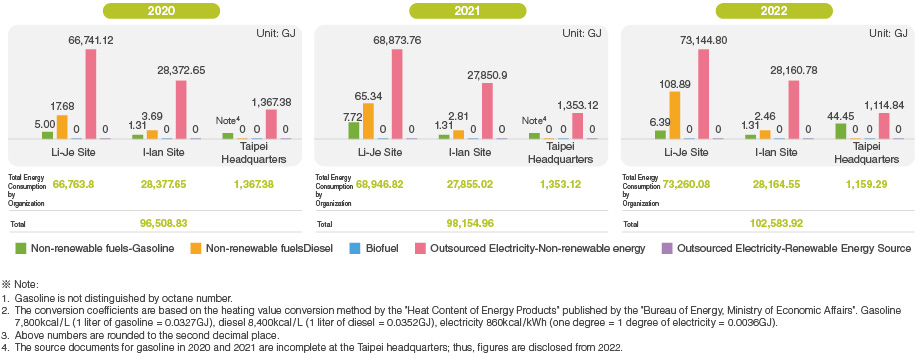

TSC primarily relies on outsourced electricity as its main energy source. In 2022, electricity accounted for 99.84% of the company’s energy consumption. Non-renewable fuel consumption, such as gasoline and diesel, made up less than 1% of the total energy consumption. In terms of energy distribution, the Li-Je site accounted for 71.41% of the company’s total energy consumption, followed by the I-lan Site at 27.46%, and the headquarters at approximately 1.13%. Over the past three years, TSC’s energy consumption has increased by 50% due to the expansion of production capacity. However, the energy consumption per unit of production value has decreased year by year at both the Li-Je Site and I-lan Site, indicating significant improvements in energy efficiency.

Since electricity is the main source of energy consumption at TSC, the energy-saving projects implemented over the past three years have focused on reducing electricity usage at our sites. These initiatives have included enhancing the heat dissipation of cooling towers, optimizing the power of chillers, and updating lighting equipment, among other measures, all aimed at achieving energy savings and reducing carbon emissions. As a result of these efforts, TSC has successfully reduced energy consumption by 510.784 GJ from 2020 to 2022.

| Site | Year | Energy Saving Item | Energy-saving Quantity (GJ) | Energy-saving Quantity as a Percentage of Total Electricity Consumption in the Year |

|---|---|---|---|---|

| Li-Je Site | 2020 | • Adjust cooling water flow rate to improve cooling tower’s dissipation | 526.29 | 0.79% |

| 2021 | • Boost chiller’s power • Reduce equipment’s ventilation • Improve the lighting in the repair area. |

1,195.76 | 1.74% | |

| 2022 | • Air conditioning system power saving | 1291.11 | 1.76% |

| Site | Year | Energy Saving Item | Energy-saving Quantity (GJ) | Energy-saving Quantity as a Percentage of Total Electricity Consumption in the Year |

|---|---|---|---|---|

| I-lan Site | 2020 | • Improvement measures for process cooling water (PCW) • Replacement of clean room light source |

323.24 | 1.14% |

| 2021 | • Improvement measures for outside air handling unit and chiller | 1,329.89 | 4.77% | |

| 2022 | • Light source replacement plan for the front TMTT station and molding press station • Replace mercury lamps in the utility apparatus room with LEDs • Exhaust pipeline merger project for site |

441.50 | 1.57% |

TSC’s Li-Je Site will begin implementing the ISO 50001 Energy Management System in 2023. Our objective is to enhance the energy efficiency of the LI-Je Site and elevate its energy performance to the highest level by utilizing PDCA (Plan-Do-Check-Action) mechanisms and relevant management strategies. Through the implementation of greenhouse gas reduction, the Company can attain its goals of sustainable operation and environmental friendliness.

Considering that the air-conditioning system at TSC’s I-lan Site operates at full capacity throughout the year, there is a risk of wasting energy resources during non-summer seasons. To address this issue, we propose implementing an improvement plan for the ice water and cooling pumps. Specifically, we plan to retrofit 3 cooling water pumps (25HP) and 3 ice water pumps (15HP) with frequency inverters in 2023. These inverters will regulate the frequency based on the equipment temperature requirements, reducing the motor running frequency when the temperature is sufficient and increasing it when insufficient. Based on current on-site data measurements, we have calculated the electricity consumption of the existing ice water pump and cooling water pump equipment for the year 2022. This system accounts for 12.7% of the total plant electricity consumption. After implementing the improvement plan, we anticipate a 4.9% reduction in site electricity consumption. Considering the estimated cost of mobile electricity, we expect an annual decrease of 350,000 kWh at a rate of NT$2 per kWh. This translates to an annual reduction of NT$700,000 in electricity expenditure. By achieving both energy-saving and cost-saving objectives, this improvement plan will contribute to the company’s overall efficiency.